Free Downloads A B

Here they are! Free Pdf downloads to assist you in your restoration project. It is our hope that providing this resource without cost will make your preservation efforts more affordable.

WhatsApp)

WhatsApp)

Here they are! Free Pdf downloads to assist you in your restoration project. It is our hope that providing this resource without cost will make your preservation efforts more affordable.

Hammer mill is the most widely used grinding mill and among the oldest. Hammer mills consist of a series of hammers (usually four or more) hinged on a central shaft and enclosed within a rigid metal case. It produces size reduction by impact.

A watermill or water mill is a mill that uses is a structure that uses a water wheel or water turbine to drive a mechanical process such as milling (grinding), rolling, or processes are needed in the production of many material goods, including flour, lumber, paper, textiles, and many metal products. These watermills may comprise gristmills, sawmills, paper mills ...

How the Sawmill Works. Below is a schematic diagram showing mechanism of the Ledyard sawmill. Click on it to enlarge. Following the diagram is an explanation of each of the subcomponents with recent photos and videos of the actual machinery.

Mill operating conditions including mill speed (for circuits with variablespeed drives), density, and total mill load; The effect of feed hardness is the most significant driver for AG/SAG performance: with variations in ore hardness come variations in circuit throughput. The effect of feed size is marked, with both larger and finer feed sizes ...

| 170 Aprill Drive | Ann Arbor, Michigan 48103 | USA

A gristmill (also: grist mill, corn mill, flour mill, feed mill or feedmill) grinds cereal grain into flour and term can refer to both the grinding mechanism and the building that holds it. "Grist" refers to grain that has been separated from its chaff in preparation for grinding

Midsized Grain Mill Designs. These grain mills should process at least 10 pounds of flour at a time. You can still use crank, gear, gravity, and electric motors to power these mills. On the other hand, you might find that cement, metal, or more durable materials will be needed for these mills. Large Grain Mill Designs. Trip and Pneumatic Hammer ...

Kent USA Manual Knee Mills are affordable, versatile, and easy to operate. Our manual knee mills are ideal for prototype, tool room and RD work, as well as part of training programs and everyday machining. You will be able to perform practically any milling operation on a knee mill.

Line diagram of ball mill with separator. Over the last few decades separator efficiency has increased from about 25% to 75% as a result of improvements in separator design. Separator particle separation performance is assessed using the Tromp curve, a graph of percentage separator feed to rejects against particle size range.

Variety of wind turbine wiring diagram. A wiring diagram is a simplified standard photographic representation of an electrical circuit. It shows the elements of the circuit as simplified shapes, and also the power and also signal connections between the devices.

The Automated Straight Line Diagrams allows users to customize pages and change the attributes that are displayed on the page. It shows a wider variety of data that is not displayed on the traditional Straight Line Diagrams which is currently provided in Portable Document Format (PDF).. The NJDOT Roadway VideoLog provides users with a windshield perspective of New Jersey''s roadways in a ...

CNC bed mill low air (BM430H,460H,560H).pdf. CNC knee mill bed mill high low CNC CNC lathe S25L hydraulic Space saver VM Diagram 2EV MMS Oil diagram for Schematic for 2EV Schematic for EV 1336 Centroid Schematic Centroid ...

The chainsaw mill, or Alaskan mill as it is sometimes called, is pretty simple. You start with a straight reference edge atop the log you want to plank up (a ladder makes a good straight edge). The ''CS mill", that is the chainsaw mill, which is the jig attachment you build, holds the chainsaw''s guide bar (GB) below and in alignment with this ...

Dec 10, 2017· An end mill''s overall reach, or length below shank (LBS), is a dimension that describes the necked length of reached tools. It is measured from the start of the necked portion to the bottom of the cutting end of the tool.

Mill PartsPrice List MP3029 Table Lock Plunger 3VS (10x13/10/16) (Each) 11 MP3030 Saddle Lock Bolt MP30301 Table Lock for Retrofited NC Mill 15 MP3030/3031 Table Lock Handle Assembly for Mill 25 MP3031 Table Lock Bolt Handle MP3035 Table Stop Bracket 45 MP3036 Socket HD Cap Screw 10x16 6 MP3037 Felt Wipers (Right) for 3VS 7

Wiring diagram for standard MicroMark 7x14 mini lathe. XMT1135 LMS 2040: 2514: Wiring diagram for late model mini mill with red and yellow emergency stop switch. FC350BJ/110V LMS 1211: 3156: Wiring diagram for late model harbor freight mini lathe with illuminated rocker power switch and safety interlock circuit. FC250BJ/110V LMS 3149

A typical layout of a mill using the kraft chemical pulping process is shown in figure 21. Mechanical, semichemical, and sulfite pulp mills differ in detail, particularly in wood preparation, fiber separation, and bleaching, but many of the downstream refining,

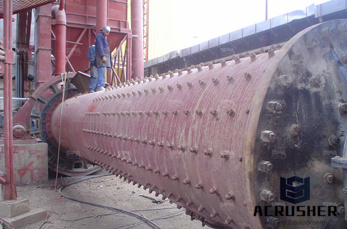

The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls. Then, discharge of ground material performed ...

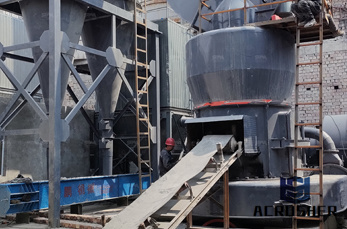

The mill design starts with the flow diagram (grinding diagram). The preparation of the mill diagram is the selection and design of order, types, number, and specification of grinding units by taking into account technical data that previously specified.

PLEASE NOTE: was founded as a public service to amateur and professional woodworkers who enjoy using and/or restoring vintage machinery. Our purpose is to provide information about vintage machinery that is generally difficult to locate. does not provide support or parts for any machines on this site nor do we represent any manufacturer listed on this ...

Charge Controller Wiring Diagram for DIY Wind Turbine or Solar Panels: This diagram shows the basic setup for those who wish to build their own Wind or Solar energy project. More infomation can be found at for looking!

My BP 1J Mill (on dealers floor)138kb. Milling Head Front View 1J 67kb. Milling Head Side View 1J 58kb. Power Feed (Original BP Type) 58kb. Powerfeed information 39kb Drawing #6 46kb. Longitudinal and Cross Feed Screw Information 56kb. 1J Parts List (H1 thru H271) 62kb. 1J Parts List (J1 thru M72) 98kb. Controls and Functions on "J" Type Head ...

The operation cam milling is used to produce the cam on the milling machine. In this operation cam blank is mounted at the end of the dividing head spindle and the end mill is held in the vertical milling attachment. 17. Thread Milling Operation. The operation thread milling produces threads using .

WhatsApp)

WhatsApp)